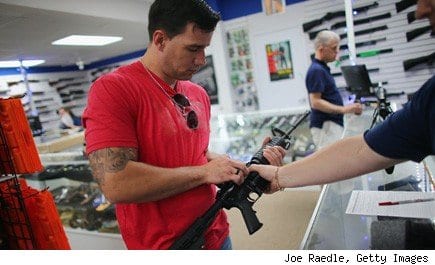

This article was originally posted By Aaron SmithGuns and ammo are selling briskly these days, and that means weapons makers are hiring. Some manufacturers are scrambling to find enough workers.

Mike Weddle, head of maintenance at Dynamic Research Technologies, an ammunition manufacturer in Albany, Mo., says he is adding 10 new hires to his staff of 35. DRT’s machine operators make between $10 and $17 an hour — a healthy paycheck in a region where it’s tough to find a job and the cost of living is relatively low.

DRT currently cranks out 80,000 bullets per shift and operates two shifts per day. But that’s not enough to meet demand. So Weddle is adding a third manufacturing shift and building an additional facility.

“Demand picked up a year ago — it quadrupled,” he said. “It just went crazy.” He says .223 caliber ammo, which is for semiautomatic rifles, is particularly difficult to keep in stock.

DRT is a tiny part of an industry that employs about 240,000 nationwide, according to an estimate from Brian Rafn, who follows the gun industry for Morgan Dempsey Capital Management. And like DRT, many of the giants in the business of making guns and ammo are also expanding.

More: Guns In The Workplace: Gun Shop Owner And Legislator Face Off

“Sturm, Ruger and Smith & Wesson have both added manufacturing capacity, which includes labor and shifts, in the past year,” said Wedbush Securities analyst Rommel Dionisio.

Caleb Ogilvie, a concealed-carry instructor who works at Cabot Gun & Ammo in Cabot, Ark., said that employees at a nearby Remington plant in Lonoke are telling him that “they’re running full swing up there, running 24-7.”

The good news for Smith & Wesson, Sturm, Ruger & Co., Colt and Remington is that they’re based in regions of New England and upstate New York where manufacturing has vanished, leaving a labor pool that’s hungry for work, according to Dionisio. He said that many of the added jobs are “temporary, contract-type hires, as opposed to full-time, permanent hires” since the companies don’t know how long the surge in demand will last.

But these companies also need highly-skilled workers. Rafn said that competition among gun makers is fierce for top-notch engineers. That’s because it’s the engineers that come up with the unique gun-design flourishes that inspire gun buyers to add to their collections.

“To get a guy to buy his 29th or 30th gun, you’ve got to come up with a whole new frame,” said Rafn. “We’re always looking at new products, and it’s these guys who design them.”

New features include ergonomic frames, triggers with innovative safeties or actions, or side-mounted laser sights, to give guns a competitive edge. Engineers with the computer-designskills to create them can easily earn $100,000 a year, he added.

More: Workplace Homicides Up 50 Percent In The Last Year

Jacob Herman, chief operating officer for Red Jacket Firearms in Baton Rouge, La., agrees that finding qualified workers is the biggest hurdle for his business, which has an 18-month long backlog of orders. Red Jacket, a family-owned company with 30 employees, makes AR15 semiautomatic assault rifles but has had to stop taking new orders for the time being.

“Finding skilled machinists and advanced skilled labor is one of the biggest problems that we face in getting products out the door,” said Herman.

“The firearms industry is fighting for the same employees as the exploding oil business, both here in the Gulf [of Mexico] and in the Dakotas,” said Herman, referring to the oil boom in North Dakota, where workers are flocking for jobs with Halliburton, Continental Resources, Hess and Whiting Petroleum.

Machinists can also go into business for themselves as gunsmiths, making about $60,000 a year repairing and maintaining firearms.

Mark Raines, who spends his days refinishing, rebarrelling and nickel-plating, said the orders are piling up at his shop, Masters of Gun and Rod, in Tallahassee, Fla.

“The demand is so high, that I’ve probably got 250 guns in here for repair at any given time,” said Raines. “You make a good living, [but] you don’t get rich. Because any time you work with your hands, you’re limited to how much you can turn out in a 24-hour period.”

Mike Weddle, head of maintenance at Dynamic Research Technologies, an ammunition manufacturer in Albany, Mo., says he is adding 10 new hires to his staff of 35. DRT’s machine operators make between $10 and $17 an hour — a healthy paycheck in a region where it’s tough to find a job and the cost of living is relatively low.

DRT currently cranks out 80,000 bullets per shift and operates two shifts per day. But that’s not enough to meet demand. So Weddle is adding a third manufacturing shift and building an additional facility.

“Demand picked up a year ago — it quadrupled,” he said. “It just went crazy.” He says .223 caliber ammo, which is for semiautomatic rifles, is particularly difficult to keep in stock.

DRT is a tiny part of an industry that employs about 240,000 nationwide, according to an estimate from Brian Rafn, who follows the gun industry for Morgan Dempsey Capital Management. And like DRT, many of the giants in the business of making guns and ammo are also expanding.

More: Guns In The Workplace: Gun Shop Owner And Legislator Face Off

“Sturm, Ruger and Smith & Wesson have both added manufacturing capacity, which includes labor and shifts, in the past year,” said Wedbush Securities analyst Rommel Dionisio.

Caleb Ogilvie, a concealed-carry instructor who works at Cabot Gun & Ammo in Cabot, Ark., said that employees at a nearby Remington plant in Lonoke are telling him that “they’re running full swing up there, running 24-7.”

The good news for Smith & Wesson, Sturm, Ruger & Co., Colt and Remington is that they’re based in regions of New England and upstate New York where manufacturing has vanished, leaving a labor pool that’s hungry for work, according to Dionisio. He said that many of the added jobs are “temporary, contract-type hires, as opposed to full-time, permanent hires” since the companies don’t know how long the surge in demand will last.

But these companies also need highly-skilled workers. Rafn said that competition among gun makers is fierce for top-notch engineers. That’s because it’s the engineers that come up with the unique gun-design flourishes that inspire gun buyers to add to their collections.

“To get a guy to buy his 29th or 30th gun, you’ve got to come up with a whole new frame,” said Rafn. “We’re always looking at new products, and it’s these guys who design them.”

New features include ergonomic frames, triggers with innovative safeties or actions, or side-mounted laser sights, to give guns a competitive edge. Engineers with the computer-designskills to create them can easily earn $100,000 a year, he added.

More: Workplace Homicides Up 50 Percent In The Last Year

Jacob Herman, chief operating officer for Red Jacket Firearms in Baton Rouge, La., agrees that finding qualified workers is the biggest hurdle for his business, which has an 18-month long backlog of orders. Red Jacket, a family-owned company with 30 employees, makes AR15 semiautomatic assault rifles but has had to stop taking new orders for the time being.

“Finding skilled machinists and advanced skilled labor is one of the biggest problems that we face in getting products out the door,” said Herman.

“The firearms industry is fighting for the same employees as the exploding oil business, both here in the Gulf [of Mexico] and in the Dakotas,” said Herman, referring to the oil boom in North Dakota, where workers are flocking for jobs with Halliburton, Continental Resources, Hess and Whiting Petroleum.

Machinists can also go into business for themselves as gunsmiths, making about $60,000 a year repairing and maintaining firearms.

Mark Raines, who spends his days refinishing, rebarrelling and nickel-plating, said the orders are piling up at his shop, Masters of Gun and Rod, in Tallahassee, Fla.

“The demand is so high, that I’ve probably got 250 guns in here for repair at any given time,” said Raines. “You make a good living, [but] you don’t get rich. Because any time you work with your hands, you’re limited to how much you can turn out in a 24-hour period.”